It has been found that screen printing techniques have been around since the start. During the Song Dynasty era in 960 AD, early artists have been using the screen printing methods; however, stencilling in its earliest form has been found in caves that date back to the prehistoric period. Several tools, materials and techniques are essential to create the diverse and interesting visual results that we see today. Now, artists, uniformed services and printing professionals use the screen printing method to create labels, posters, stencil graffiti, t-shirts and signs.

The earliest recognisable method of screen printing appeared roughly 1,050 years ago in China, The Song Dynasty which was credited a navy, stands as an era that saw the developments in painting and other forms of artist expression. Screen printing, which is a technique that uses mesh and ink-blocking methods developed after its ancestor stencilling. It was then adapted by other Asian countries like Japan and was furthered by creating newer methods. Roughly 40,800 years ago, early humans created hand stencils using a range of techniques. Stencilling and the screen printing method have much in common and the earliest form of artistic expression that evolved into the screen printing technique covers the wall of European caves.

Screen printing was generally introduced to Western Europe from Asia sometime in the late 18th century, but did not gain recognition until silk mesh was more available to trade from the east.

Several printers experimented with photo reactive chemicals in the early 1910s. They used the well-known actinic light-activated cross linking or hardening traits of potassium, sodium or ammonium chromate and dichromate chemicals with glues and gelatine compounds. Roy Beck, Charles Peter and Edward Owens experimented and studied with chromic acid salt sensitised emulsions for photo-reactive stencils. This trio revolutionised the commercial screen printing industry by introducing photo-imaged stencils to the industry, though it took many years for this method to be accepted, using sensitizers that are safer and less toxic than bichromates. Currently there are large selections of pre-sensitized and “user mixed” sensitized emulsion chemicals for creating photo-reactive stencils.

To distinguish the artistic application of screen printing from the industrial use if the process, a collection of artists who later formed the National Serigraphic Society created the word Serigraphy in the 1930s. Serigraphy was from the Latin word ‘sēricum’ and the Greek word ‘graphein’ which means to write or draw.

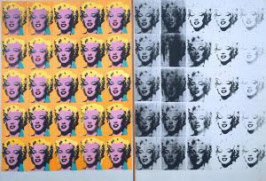

Andy Warhol is credited for popularising screen printing/serigraphy in the United States in the 1960s. Warhol is particularly identified with his 1962 image of icon Marilyn Monroe.

American entrepreneur, artist and inventor Michael Vasilantone started to use, develop and sell a rotary multi-colour garment screen printing machine in 1960. The original rotary machine was manufactured to print logos and team information on bowling garments but soon directed to the new craze of printing on t-shirts. The Vasilantone patent was licensed by multiple manufacturers, the resulting product and boom in printed t-shirts made the rotary garment screen printing machine the most popular device for screen printing in the industry.

In June 1986 Marc Tartaglia, Marc Tartaglia Jr. and Michael Tartaglia created a silk screening device which is defined in its US Patent Documents as “Multi-coloured designs are applied on a plurality of textile fabric or sheet material with a silk screen printer having seven platens arranged in two horizontal rows below a longitudinal heater which is movable across either row”

Graphic screen printing is widely used today to create many large batch produced graphics such as posters or display stands. CMYK (cyan, magenta, yellow and black (‘key’)) can be used to create full colour prints.

The screen printing technique involves mesh covered frame, or screen, and a stencil. The stencil created from shapes, letters or words, blocks a portion of the screen. The screen sits atop the item that will receive the image, a shirt or poster, for example. The item is usually called a substrate. The artist or print person places ink on top of the screen and stencil. They then squeegee the substrate to create a sharp image on the substrate.

Multiple forms of stencilling exist and are limited to an artist’s imagination. One popular stencilling technique is direct photographic emulsion which involves stencils, mesh screens and light sources. Stencilling techniques have evolved substantially throughout history, from red ochre cave prints to aerosol graffiti. Today, artists and print makers use airbrush, micro-stencilling and photographic emulsion methods to create a wide range of interesting artwork.

The screen printing process requires a number of materials, supplies and tools. Inks, screens, glues and squeegees are the basic materials required to create screen printed images. Multiple types of inks are available, including plastisol, water based and discharge inks; and they provide a range of effects and colours saturation that give different artistic projects a distinctive twist. In addition to coloured inks, there are metallic and glosses that can create different yet interesting finishes.

Today, electronic screen printing (a recent innovation) provides manufacturing and the environment a number of benefits. Electronic screen printing techniques with the removal of particles and solvents, produce lint-free surfaces and are eco-efficient. Electronic screen printing requires a number of semiconducting materials. Screen printed solar cells, solar photovoltaics and solar wafers are used to produce electronic screen printing components.

Screen printing offers itself well to printing on canvas. Andy Warhol, Rob Ryan, Blexbolex, Arthur Okamura, Robert Rauschenberg, Roy Lichtenstein, Harry Gottieb and many other artists have used screen printing as an expression of creativity and artistic image.

Over time screen printing has evolved into many things, one of which is Industrial. This means that the prints purpose is not to carry a promotional message, like a t-shirt, but is part of a manufacturing process that either permits the function of the product or enhances its appearance or decoration.

As you scan your desk you might find a couple of industrial screen printed objects scattered around. Your keyboard for example, or even your calculator. These objects have been printed to help you use them, not to promote a certain message or have an artistic design on them (Well, apart from the logo)

If you think about it, many electronic items would be useless without industrial printing; unless you have studied and memorised your keyboard. The printed sections show you vital information that is essential for the use of the equipment.

Here at Customark we offer a direct printing service onto panels and chassis that are supplied by you. If required, we can also source panels on your behalf, this provides a complete turnkey operation that helps you avoid unnecessary logistics in dealing with multiple suppliers.

Our level of knowledge and experience lets us work to extremely particular productions and a high level of quality as well as detail.

We are also able to produce multi-colour panel prints on unusual shapes and can print onto almost any surface.

If you want to find out more then please get in touch, we are always happy to help. Call us on 01384 264700 or email us sales@customark.co.uk